Categories: Electrician at home, Electric installation work

Number of views: 49892

Comments on the article: 5

Terminal blocks for connecting wires and cables

What are the terminal blocks for?

Installation of cable lines and wires ends with their connection. An electrical connection that ensures the health of the entire circuit. This connection must be reliable, must not allow electrical losses and must be protected from accidental access, that is, it must ensure safety.

Installation of cable lines and wires ends with their connection. An electrical connection that ensures the health of the entire circuit. This connection must be reliable, must not allow electrical losses and must be protected from accidental access, that is, it must ensure safety.

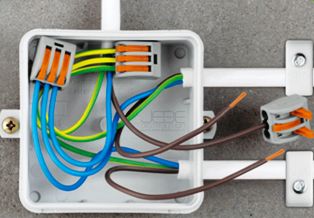

Safety is achieved by using special enclosures and junction (distribution) boxes. And the other two necessary conditions are ensured by the use of special certified clamps or terminal blocks. We will talk about the diversity of the latter. But first, we answer the question: “And why exactly the terminal blocks, in fact?”

In fact, why can not do ordinary twisting? After all, one often hears or reads that the correct twisting will be more reliable than many terminal blocks. So what was the matter? But it was because it was about the correct twist. Moreover, operated in certain conditions.

About, how to make the right twist almost treatises are being written (despite the seemingly unlawfulness of twisting as such). But in reality, under what conditions this particular twist can be used, only the heart of the installer can whisper on the basis of his own (installer) experience.

That is, making the right twist is not so easy. And even a specialist cannot unambiguously determine whether this particular twist will last happily for a given given conditions or not.

At the same time, the terminal blocks are factory products that have been tested and received a certificate. Yes, we all know that everything is easily faked with us, but still each terminal block, even a fake one, has a long-tried and tested design. The terminal strip markings specifically indicate its current and voltage rating, as well as the limits of the cross-sections of the connected wires, and in some cases even the type of these wires.

Thus, the terminal blocks assume the minimum qualification requirements for the installer. It is enough to read the information on the terminal strip, familiarize yourself with its labeling - and you can safely judge whether this terminal strip will work in these conditions.

That is why the current rules suggest not trying to figure out the level of practical knowledge of each electrician, but simply use the terminal blocks.

What are the terminal blocks?

The main types of terminal block designs have been known for a long time and are familiar to every installer. Conventionally, they can be divided into screw and screwless (they are spring). Both those and others are products in a plastic (kapron, carbolite) case, containing a contact group.

“Contact group” - this is the very mechanism that connects the wires. The electrical connection is usually provided not directly, but through the metal of the contact group. And what's more: in many cases for using the terminal block wire must be terminated. And this means that the electrical circuit of the connection takes on a seemingly quite complex character: “wire1 is its tip — metal of the contact group — tip of wire2-wire2”.

An exception may be only situations when the wires are connected with solid conductors, which in many cases can be clamped in the terminal blocks without the use of lugs.

And at each contact transition, minimal losses and almost complete absence of heating due to such factors are ensured:

-

creating the optimal pair of metals in each bundle (tip-wire, tip-contact group, and so on);

-

the use of a special quartz-vaseline lubricant to prevent the formation of an oxide film on the surface of aluminum conductors;

-

terminal block design, which provides for clamping the wire or terminal in the contact group.

The first factor determines the choice of metal for the manufacture of the contact group. Wires and lugs are almost always copper, or aluminum, or tinned copper. Good and reliable contact with these metals is provided by steel, brass, as well as some special alloys. Of these, the contact groups of the vast majority of terminal blocks are made.

The second factor does not need additional comments, although the use of lubricant is often neglected. But, for example, in the composition terminal blocks wagodesigned to connect aluminum conductors, such lubrication is already provided by the manufacturer.

Well, and finally, the third factor and reveals the fundamental differences between screw and spring terminal blocks. In screw terminal blocks, the clamping force is created by an ordinary threaded screw, which presses the wire to the contact, most often corrugated, surface. And in the spring terminal block, the clamping force is created by a deformed spring.

The spring can be bent almost instantly and a wire inserted into the terminal block. This means that spring terminal blocks significantly save installation time compared to screw terminal blocks, the screws of which have to be long and tedious to turn with a screwdriver, holding the clamped wire in one hand.

But often, screwless terminal blocks are accused of inability to hold an increased current load: the spring loses its elasticity under the influence of elevated temperatures and the contact worsens its condition.

However, by and large, all this means only that the spring terminal blocks should not be overloaded with current. They hold the rated load perfectly.

Terminal Block Manufacturers

Among the leaders in the production and in the quality of screwless terminal blocks manufactured, it should be noted the already mentioned company Wago, as well as Phoenix Contact. The latest manufacturer is also known for its screw terminal blocks.

Domestic terminal block manufacturers are significantly lagging behind in terms of quality, but they are slightly winning in terms of prices for their products. Klemmniki are in the range of production of literally every second Russian plant of electrical products. But the real popularity was gained only by insulated screw terminal blocks of the ZVI series. So far, instead of domestic terminal blocks, electricians often prefer PPE caps or elementary wire welding.

See also on this topic: Modern terminals for connecting wires andWago terminal blocks in home wiring

See also at e.imadeself.com

: