Categories: Featured Articles » Electrician Secrets

Number of views: 242620

Comments on the article: 18

How to make a good twist of wires

This article has a somewhat provocative title. I am sure that there will immediately be people who will instructively write, saying that twisting is illegal and according to the PUE, twisting of wires is prohibited.

This article has a somewhat provocative title. I am sure that there will immediately be people who will instructively write, saying that twisting is illegal and according to the PUE, twisting of wires is prohibited.

Nobody argues with this. If not for the fact that, in spite of everything that is written in the EMP, the vast majority of wire connections in the territory of the former large Soviet country are still twisted.

I will not argue that very good twisting of wires - This is the most reliable and high-quality way to connect wires, although they constantly try to prove it to me. It seems that someone even made a measurement and compared the voltage drop on the twist and on a whole piece of wire, so it turned out to be less on the twist. Perhaps this is something from the field of mythology among electricians. We will simply proceed from the fact that good twisting can be called one of the stages and a very important element of such methods of connecting wires, such as soldering or welding.

Before discussing further about the correct twisting, let's dwell on what will happen if the wires are connected just like that, without technology, "how it happened." In this case, at the point of contact of the two wires occurs contact resistance. There are two reasons for this - a decrease in the cross-sectional area of the wire at the point of contact (mainly due to microprotrusions during connection) and the presence of an oxide film on the wires.

Oxide film - the result of the interaction of the atoms of the metal of which the core consists of oxygen. Such an oxide film has a very decent resistivity. The oxide film is absent only in noble metals - gold, platinum, etc. (for that they are also “noble”, which do not react with anyone). In silver, the specific resistance of the oxide film is the same as in the metal itself, so silver is actively used in the contacts of various electrical devices.

Oxide film - the result of the interaction of the atoms of the metal of which the core consists of oxygen. Such an oxide film has a very decent resistivity. The oxide film is absent only in noble metals - gold, platinum, etc. (for that they are also “noble”, which do not react with anyone). In silver, the specific resistance of the oxide film is the same as in the metal itself, so silver is actively used in the contacts of various electrical devices.

When the wire is heated by the current passing through it, the transition contact resistance increases even more, because the generated heat is not completely removed to the environment, but also heats the wire itself, including twisting.

As a result, all this can lead to an avalanche-like process, when the place of twisting is more and more heated. Here is one of the causes of fires due to the so-called "faults in the wiring."

I met one case when an aluminum twist in a neighbor’s country house stood for only one day. The reason for this is not only the presence of poor-quality twisting, but also the material of the conductive core of the wire. Why copper wire is always better than aluminum the site has already been written.

The most interesting thing is that no circuit breakers and fuses in the switchboard will help in this case, because they respond to an increase in current in the circuit. In our case, the current does not change, it just more and more warms up the contact point of the two wires.

Based on this, we can conclude that A good twist of the wires is necessary, first of all, so that the transition contact resistance always remains stable and does not change over time.

So, what do you need to make a good twist of wires?

First you need to remove the insulation without damaging the wire core. The exposed part of the vein is cleaned of dirt with a clean rag soaked in acetone or white spirit. Then we clean the veins with a metal brush or sandpaper to a metallic luster.

Next, we twist the stripped veins with two pliers. To do this, bend the ends of the wires at an angle of 90about at a distance equal to 7-10 diameters of the core from the insulation slice, and we start them for each other. We wind with pliers 5-7 turns of one core to another.

We wind 5-7 turns of another core and seal the connection with pliers, i.e. we tighten with two pliers the turns of the veins in opposite directions. Then tightly bend the ends of the wires.

In order to make a branch, it is necessary to wind 10-15 turns of a branch core around the main core. Seal the branch with two pliers, tightening the turns of the core by moving them in opposite directions. Then bend the end of the branch core tightly. After all these operations, the twist will be mechanically strong and reliable.

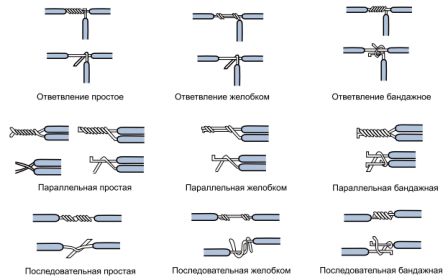

There are many other ways to connect twisted wires. All of these methods are even given characteristic names.

For example, here are some ways that are shown in one famous book for young electricians:

The option that I described in this article, using two pliers, has been tested by practice and has never failed.

After creating a high-quality twist, the wires can be soldered (little used due to the complexity), welded (in one of the articles on the site it was somehow proved that welding is the best way to connect wires).

A good twist is needed, for example, for a more modern and less time-consuming way of connecting wires - when using shrink tube, which is a good alternative to electrical tape.

In appearance, it looks like an ordinary cambric, which is worn on a twist with a margin in both directions. Then the heat shrink tube heats up (for this you can use a regular lighter, but it is better to use an electric hair dryer), wraps tightly around the cable and reliably insulates it.

Do the twisting correctly!

If you have your favorite options for connecting wires - share and tell about it in the comments to the article!

See also at e.imadeself.com

: