Categories: Featured Articles » Electrician Secrets

Number of views: 43327

Comments on the article: 8

Modern terminals for connecting wires

If someone still believes that there is nothing better for connecting the wires than stripping their ends with a knife, twisting them, and wrapping them with electrical tape, then he is behind the times. Today, there are already plenty of alternative devices that greatly facilitate the process of connecting wires, and at the same time are quite reliable. Time twist will soon sink into oblivion, for they are replaced by a variety of terminals.

If someone still believes that there is nothing better for connecting the wires than stripping their ends with a knife, twisting them, and wrapping them with electrical tape, then he is behind the times. Today, there are already plenty of alternative devices that greatly facilitate the process of connecting wires, and at the same time are quite reliable. Time twist will soon sink into oblivion, for they are replaced by a variety of terminals.

Why are the terminals good? Such as, connect aluminum wire to copperso that the connection is reliable and durable?

It is absolutely impossible to twist copper with aluminum, because then a galvanic pair is formed, and corrosion will simply destroy the connection, it does not matter what size the current will pass through the twist, it will break down sooner or later, and if the current is greater, turn on and off the devices more often, then the twisting resistance will increase faster, over time, the heating of the twisting point will become more and more.

In the end, it is fraught with fire, or at best - the smell of molten insulation. The terminals in this situation would be saved, and the matter would not have come to the destruction of the place of contact.

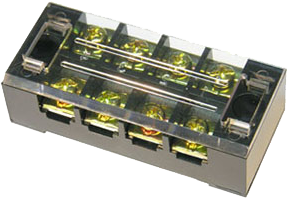

The simplest solution is to put polyethylene terminal block. Polyethylene terminal blocks are sold today in every electrical goods store, and are not expensive. Several brass tubes (sleeves) are arranged in a row inside the polyethylene frame, in which the ends of the wires to be connected are clamped with two screws. If desired, you can cut off how many tubes in polyethylene are needed, and connect as many pairs of wires as you need.

However, not everything is so rosy, aluminum flows under the pressure of the screw at room temperature, so from time to time, once a year, it will be necessary to tighten the connection. Otherwise, when it comes to connecting copper conductors, everything will be fine.

If the aluminum wire staggering in the terminal block is not pulled in time, then the end of the wire that has lost its former contact will spark and heat up, and this is fraught with fire. You can not clamp multicore wires into such a terminal strip without auxiliary pin terminals, which we will talk about later.

If you simply clamp the stranded wire into such a terminal strip, then the pressure of the screw on the thin veins, combined with rotation and an uneven surface, will lead to the fact that part of the veins will become unusable, and this threatens to overheat. If a stranded wire fits tightly on the diameter of the sleeve, this is the most acceptable connection option, because there is less risk of connection failure.

As a result, we can conclude that polyethylene terminal blocks are good for single-core, and only for copper wires. If you need to clamp a stranded one, you will have to put on an auxiliary tip, which will be discussed later.

The next option is convenient connection terminals - terminals on plastic pads. Such terminal blocks equipped with transparent covers, which can be removed if desired. Fastening is very simple: the stripped end of the wire is pushed between the pressure and contact plates, and pressed by means of a screw.

What are the advantages of such terminal blocks? Firstly, unlike polyethylene terminal blocks, plastic terminal blocks have an even steel clamp, there is no direct screw pressure on the wires. The clamping part has a recess under the wire. As a result, these terminal blocks are applicable for connecting groups as single and stranded wires. Why groups? Because this terminal block can not be cut like polyethylene.

Next are self-locking terminals, an example of which is WAGO Series 773. These are express terminals for quick one-time wiring.The wire is pushed all the way into the hole, and there it is automatically fixed by the pressure plate, pressing the cores to a special tinned tire. The pressing force is maintained all the time thanks to the material of the pressure plate.

These express terminals are disposable, but in principle, you can pull out the wire by quietly rotating it during pulling. But if you pull out the wire, then the next connection is better to do it already in the new clamp, fortunately, they are not expensive, 10-20 times cheaper than the terminal blocks.

The inner copper plate has tinning, and allows you to fix at least aluminum, even copper wires. The clamping force is maintained continuously, and the wire does not have to be pressed once a year, as happens with the terminal blocks.

Inside there is also a lubricant based on quartz sand with technical petroleum jelly, for abrasive, eliminating the oxide film, action on the surface of the wire, which prevents, thanks to petroleum jelly, its appearance again. These express terminals are transparent and opaque. In any case, plastic does not support combustion.

WAGO branded express clamps suitable for connections with an estimated current of up to 25A. Terminals of other manufacturers may suffer from heating, for example, the clamping force of the spring contacts will weaken, so use only branded, well-proven terminals.

Suitable as reusable terminals 222 series from WAGO. These are terminal blocks with lever clamps. Here you can also clamp wires of various types. The fastening process is simple: the lever rises, the end of the clamped wire is inserted, the lever is pressed - fixing occurs.

This clamp is reusable. When raising the lever, the fixation is removed, one wire can be pulled out and another inserted. This type of terminal is ideal for re-configuring conductor groups. Withstands currents up to 32 amperes without overheating. The design of the clamp is a bit like a disposable express clamp, the difference again is the ability to repeatedly switch the connected conductors.

Next we will consider scotch-lock couplings. These are disposable couplings for low current conductors. Using tape locks, you can connect telephone wires, low-power LED lights, etc. The essence of this fixture is mortise contact.

Several wires, directly in isolation, are inserted into the sleeve, then crimped with pliers. Installers of structured cabling systems love Scotch Loki. Scotch locks allow you to connect wires without the need to strip them. A plate with cutting contacts simply cuts into the insulation, and comes in contact with the conductor, with the core.

Scotch locks come in two and three cores. The peculiarity of such terminals is that they are cheap, waterproof, versatile, and do not require stripping of the ends, but are crimped with simple pliers. A hydrophobic gel is present inside the coupling to protect the contacts from moisture and corrosion.

If you need to replace the connection, the adhesive tape is simply cut out with pieces of wire, and a new one is put.

When you need to connect several wires into one powerful unit, for example, simply combine them, or for laying on the terminal block, apply sleeves. The sleeves are most often used universal, they are usually tinned copper sleeves in the form of tubes, or in the form of flat tips with a mounting hole.

The wires are inserted into the sleeve, and crimped with a special tool - a crimper. Crimper - this is crimping pliers. The huge advantage of the sleeves is that such crimping does not create increased resistance at the junction. Sleeves in the shape of a flat tip with a hole are convenient when you need to fix a wire or bundle of wires on the housing with a screw. Just pick up a sleeve of a suitable diameter, crimp, and attach the tip to where you need it.

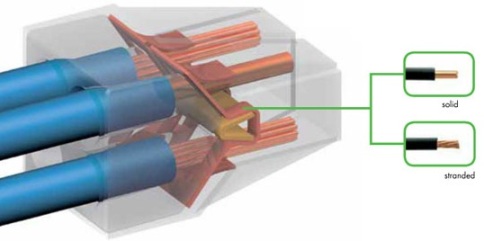

To connect stranded wires, to combine single-core wires with stranded wires, or simply to fix them in terminal blocks, apply pin sleeve lugs.

The stranded wire is conveniently inserted into the lug, the lug together with the wire is pressed, after which the stranded wire can be fixed in any terminal block, even in polyethylene, without fear that the connection will be broken.

Decisive here is the correct choice of the diameter of the tip, it must correspond to the total diameter of the crimped, bundled, lived so that the wires then do not pop out.

To crimp the pin tips, you can do with pliers or use a screwdriver and a hammer.

See also at e.imadeself.com

: