Categories: Featured Articles » Home automation

Number of views: 17304

Comments on the article: 10

Automation of the heating process using infrared film

The problem of finding alternative methods of heating apartments and houses does not lose its relevance. One of the modern solutions for space heating is the installation of infrared films. All their advantages are described in detail by sellers of such products.

The problem of finding alternative methods of heating apartments and houses does not lose its relevance. One of the modern solutions for space heating is the installation of infrared films. All their advantages are described in detail by sellers of such products.

We give a specific example of the use of this type of heating. The owners of a three-room apartment building, it was decided to heat their home using infrared films. They turned to the appropriate company, whose specialists performed the installation and commissioning of the necessary equipment.

A temperature controller was installed in each room to control the temperature. The heating performance was tested, the owners performed the calculation, and the company employees left.

After a short period of using infrared heating, a serious problem arose. The fact is that the power of a meter of a square heating film is 250 W, if you multiply this figure by the total film area in all rooms, we get a power of about 7 kW. According to the technical conditions, a 16 A circuit breaker was installed on the electrical input of this apartment building, on which there is a seal.

It turned out, if the thermostats gave the command to simultaneously turn on the heating of all rooms, the introductory machine knocked out. The owners had to manually control the heating process, constantly turning on and off the circuit breakers in each room, preventing the heating of the milestones of the rooms simultaneously.

This problem could be solved by installing a larger circuit breaker at the input. But since the latter is sealed, the permission of the organization supplying electricity would be required. As you know, getting any permits from government agencies requires a lot of nerves and financial costs.

It was decided to do it easier, namely, to organize automatic control of heating, which would not allow the simultaneous inclusion of the load and knocking out the machine. For implementation, a commercially available programmable real-time relay was used.

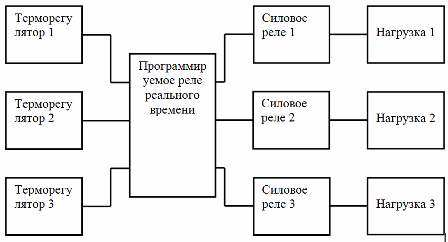

It has four contacts that close at a specific time given by a person. The contacts are designed for a current of not more than 10 A, therefore, power relays are additionally used in the circuit. To manually turn off the heating of each room there is an automatic machine. It all looks like this:

Only the heating of the three largest rooms was controlled, two of which are 1.8 kW each and one 2.6 kW. The work of heating the bathtub and the corridor was left independent, due to the small electric power (the far right two machines).

Automatic control of the heating process is as follows: three thermostats installed in each room control the temperature. When it falls below the set value, the thermostat, closing its contact, sends a signal to the time relay. The relay, in turn, passes a signal to the corresponding power relay from only one thermostat, allowing you to heat only one of the three rooms. Each subsequent hour, the time relay allows heating of the next room, prohibiting the heating of the other two.

After starting the system, the knockout of the input automaton was no longer repeated.

See also at e.imadeself.com

: