Categories: Featured Articles » Home automation

Number of views: 48958

Comments on the article: 5

Temperature sensors. Part Four A few more types of temperature sensors

In the previous parts of the article, thermistors and thermocouples. This article will talk about other types of temperature sensors.

In the previous parts of the article, thermistors and thermocouples. This article will talk about other types of temperature sensors.

Temperature sensors from diodes and transistors

In the same temperature ranges as in semiconductor thermal resistances, ordinary semiconductor diodes or pn junctions of transistors.

The use of these devices is explained by the fact that they have a temperature coefficient of voltage TKN. For all semiconductors, it is negative and approximately the same: -2mV / ° C. To verify this, it is enough to do the simplest experiment described below.

If digital multimeter of Chinese manufacture at room temperature to “ring” silicon diodes or transistor junctions, then the numbers about 690 - 700 are displayed on the indicator. For germanium semiconductor devices the readings will be 400 - 450, however, germanium devices are currently used very rarely. This is nothing more than the voltage drop shown in millivolts at the p-n junction in the forward direction.

If at the time of such a measurement the diode or transistor is slightly warmed up, at least soldering iron, then the readings will decrease. Moreover, the greater the degree of heating, the more noticeable is the change in the readings of the device in a smaller direction. Most often, such sensors are used in various electronic circuits, for example insound amplifiers to stabilize the operation modes of the circuit.

Specialized Semiconductor Sensors

It is worth mentioning here precision analog temperature sensor LM335AZ, which is one of the varieties of an adjustable zener diode. It is appropriate to recall here Zener Diode TL431. The sensor was calibrated during its manufacture at the factory, so there is no need to do an excruciating multi-stage adjustment in the manufacture of the thermometer or thermostat.

It is worth mentioning here precision analog temperature sensor LM335AZ, which is one of the varieties of an adjustable zener diode. It is appropriate to recall here Zener Diode TL431. The sensor was calibrated during its manufacture at the factory, so there is no need to do an excruciating multi-stage adjustment in the manufacture of the thermometer or thermostat.

According to the technical documentation, the LM335AZ has a positive temperature coefficient of 10mV / ° K. To convert the usual degrees of Celsius to degrees Kelvin, you should use the formula t ° K = 273 + t ° C. According to this formula, at 0 ° C, the sensor output will have a voltage of (273 + 0 ° C) * 10mV / ° K = 2730mV, and at a temperature of, for example, 50 ° C, (273 + 50 ° C) * 10mV / ° K = 3230mV.

Such wonderful properties allow you to create using this sensor thermostats, just temperature meters, as well as schemes for compensating the temperature of the cold junction of thermocouples, as will be discussed a little higher. All of the mentioned schemes are quite simple, they can be found in the technical documentation, or as it is called, date sheets (Data Sheet). Date shields are fairly easy to find on the Internet, though in English.

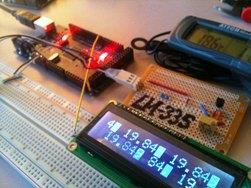

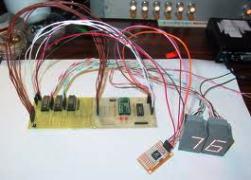

Temperature sensors for microcontrollers

In modern conditions, more and more different schemes are performed on microcontrollers, including all kinds of temperature meters. If the measured temperature does not exceed 125 ° C, then it is quite possible to use semiconductor sensors such as DS1620, DS1820, DS1B820 and the like.

In modern conditions, more and more different schemes are performed on microcontrollers, including all kinds of temperature meters. If the measured temperature does not exceed 125 ° C, then it is quite possible to use semiconductor sensors such as DS1620, DS1820, DS1B820 and the like.

When calibrated at the factory, the sensors do not need calibration and adjustment, and the measured data is transmitted digitally to the microcontroller. Further use of the obtained temperature values is determined by the controller software.

In addition to working directly with the microcontroller, these sensors have thermostat mode: it is enough to program any of them into this mode in order to control the operation of the heater according to the “on / off” principle when the temperature points indicated during programming are reached.But if other points are needed, then their reprogramming is necessary, which can be considered as a lack of sensor data.

In cases where the temperature measurement range is significantly higher than the above values, are used thermocouples.

Old primitive temperature sensors

Despite the presence of such a number of temperature sensors, still quite primitive sensors are widely used. These are, first of all, sensors based on bimetallic plates most commonly used in electric irons and electric fireplaces, as well as gauge type temperature sensors or expansion sensors. They use the expansion of a liquid in a closed volume.

Despite the presence of such a number of temperature sensors, still quite primitive sensors are widely used. These are, first of all, sensors based on bimetallic plates most commonly used in electric irons and electric fireplaces, as well as gauge type temperature sensors or expansion sensors. They use the expansion of a liquid in a closed volume.

One of the varieties of such a sensor is equipped, for example, with heating elements of Aricton domestic boilers. On one base is the heater itself, a tubular temperature sensor and an adjustable contact: as soon as the set temperature was reached, they turned off. The design is so simple that it contains only one installation thread and two terminals for connecting to the network.

Somewhat more complicated industrial temperature gauge sensors. A capillary with a liquid is connected to a pressure gauge with a scale, the end of which is in contact with the medium being measured. The scale of such a pressure gauge is calibrated in degrees centigrade, and the arrow is equipped with a system of contacts with which you can set the limits of temperature change. The contacts, of course, can control the operation of a heater, or simply an alarm.

Boris Aladyshkin

See also at e.imadeself.com

: