Categories: Featured Articles » Interesting electrical news

Number of views: 344335

Comments on the article: 22

What is a welding inverter and how does it work

Professional welders, and just those who like to do something at home with welding, have recently been able to significantly ease their work. Appeared on sale welding invertersthat allow you to make a quantum leap in electric welding.

Professional welders, and just those who like to do something at home with welding, have recently been able to significantly ease their work. Appeared on sale welding invertersthat allow you to make a quantum leap in electric welding.

It is enough to recall just the heavy lifting transformers and rectifiers produced earlier. All other things being equal, the weight of the welding inverter is an order of magnitude less than that of any other welding machine, and this significantly increases the productivity of welding.

Welding inverters are the most advanced welding machines, which currently almost completely overshadow the classic welding transformers, rectifiers and generators.

The principle of operation of the welding inverter

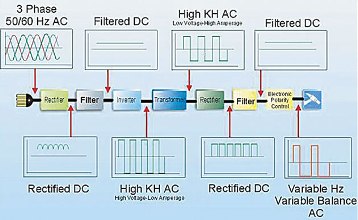

Alternating current from a consumer network, with a frequency of 50 Hz, arrives on the rectifier.

The rectified current is smoothed by the filter, then the resulting direct current is converted by an inverter using special transistors with a very high switching frequency into alternating, but already high frequency 20-50 kHz.

Then, the high-frequency alternating voltage drops to 70-90 V, and the current strength accordingly rises to 100-200 A.

High frequency is the main technical solution that allows you to achieve tremendous advantages of the welding inverter, when compared with other power sources of the welding arc.

Welding Inverter Device

In an inverter welding machine, the strength of the welding current of the desired value is achieved by converting high-frequency currents, and not by converting the EMF in the induction coil, as occurs in transformer devices. Preliminary conversions of electric currents make it possible to use a transformer with very small dimensions.

For example, to get a welding current of 160A in the inverter, a transformer weighing 250 g is enough, and a copper transformer weighing 18 kg is needed on conventional welding machines.

How the welding inverter is arranged and working on the video:

Advantages and disadvantages of welding inverters

The main advantage of the inverter is the minimum weight. In addition, the ability to use electrodes for welding both AC and DC. What is important when welding non-ferrous metals and cast iron.

Inverter welding machine has a wide range of welding current adjustment. This makes it possible to use argon-arc welding with a non-consumable electrode.

In addition, each inverter has functions: "Hot start" (hot start) to ignite the electrode, the maximum current "Anti-Sticking" with a short circuit, the welding current is reduced to a minimum, which does not allow the electrode to stick when it touches the part, Arc Force - to prevent sticking at the moment of detachment of a drop of metal, the current increases to the optimum value.

Among the disadvantages of welding inverters can be called a high cost (2 to 3 times more than that of transformers). Like any electronics, inverters are afraid of dust, so manufacturers recommend at least twice a year to open the device and remove dust. If he works at a construction site or production, then more often, as pollution. And like any electronics, welding inverters do not like frost.

So at temperatures below -15aboutUsing the inverter is not possible in all cases, depending on what parts the manufacturer used. Therefore, in such conditions, you need to look at the technical specifications declared by the manufacturer.

And one more, the length of each of the welding cables when connecting the welding machine should not exceed 2.5 meters, but you just need to get used to it.

Welding Inverter Front Panel

Welding inverters - quality and convenience of welding

Arc welding is a responsible job. For its implementation, the welder must have sufficient practical experience and knowledge of theory. Welding inverters simplified the process and solved many of the questions that arose.

The first problem solved is the ignition of an arc. For previous welding transformers, the output voltage is proportionally dependent on the input. The low voltage, common in our networks, does not give the opportunity to ignite the arc, the electrode begins to "stick".

When a transformer current is added, on the contrary, the metal is “burned out”. The device of welding inverters is such that the voltage at the output does not depend on the voltage at the input, and the installed welding current is kept constant regardless of the mains voltage. Inverters prevent sticking of the electrodes and easily create a stable arc.

When working with conventional devices, it is possible to “burn” or “not burn” metal. This is due to the fact that they poorly hold the required amount of welding current. After all, it changes and depends on the network voltage.

When the metal is “burned”, the weld is weakened, holes and sinks form in it. In case of “under-burn”, the seam is also weakened. At the welding inverter, the current is set by the potentiometer according to the welding current scale and remains unchanged.

It is difficult for a novice welder to learn how to hold an arc. After arcing, the electrode is given a slope of approximately 15 degrees and must be moved relative to the junction of the parts. The slope can be either in the direction of movement of the electrode, or in the opposite. Along with the longitudinal movement, it must be moved perpendicular to the seam. Associated with this is the length of the arc.

The main types of electrodes are provided for operation with a short arc. Therefore, it is necessary to constantly move the electrode in a perpendicular direction so that there is a gap of about two diameters from the electrode to the parts to be welded.

Welding inverters are able to strictly maintain the selected current and also it is constant. These factors make it possible not to be particularly critical about the length of the arc, which facilitates the work of the welder, especially the beginner, and the quality of the seam in this case is no longer associated with the length of the arc.

When it is not possible to arrange parts horizontally, you need to remember that molten metal undergoes gravity in the same way as a drop of water.

When working with ceiling and vertical seams, you need to stop in a timely manner and wait until the molten drop inside the seam cools slightly, and immediately "set fire" next to the next arc, moving higher and higher along the seam. Such welding is called “tack”. Using a welding inverter, mastering the “tack” is not difficult even for a beginner.

Experience shows that welding inverters facilitate “ignition”, control the arc, eliminate “sticking”, and do not require special skills to handle themselves. All this makes inverters profitable for use in the field of professional construction and home repair.

Inverter Type Welding Machine

How much electricity does the welding inverter consume in various operating modes? Watch the video:

How to choose a welding inverter

Depending on where the welding machine will work, you need to buy a household or professional inverter. The difference between them in the length of time.

A professional welding inverter is designed for an 8-hour working day, while a household inverter will require after 20-30 minutes of work, a break of 30-60 minutes, so household ones are cheaper. There are also industrial inverter welding machines that are designed to work for a long time in difficult conditions.

For a home, a welding inverter with a maximum welding current of 160 A is enough. But this is with a voltage of at least 210 V. In a low mains voltage, it is better to buy a 200 A inverter.

Welding inverters "Resanata":

Almost all world leaders in the field of welding production are focused mainly on the development and production of inverter welding power sources. Of the most well-known manufacturers, it is possible to note the Italian “Selco” and “Helvi”, the French “Gysmi”, the Korean “Power Man”, the German “Fubag”, there is also a Russian inverter welding machine “Torus”.

Do you use a welding inverter? Share your impressions!

See also at e.imadeself.com

: