Categories: Featured Articles » Sharing experience

Number of views: 22084

Comments on the article: 3

Advantages and disadvantages of inverter welding machines

For a long time you will not surprise anyone with a welding inverter. And there is nothing unusual in this, because it is much more convenient for any welder to operate with a compact and mobile device than with a heavy iron transformer. The subject of this article, however, will be precisely modern welding inverters.

For a long time you will not surprise anyone with a welding inverter. And there is nothing unusual in this, because it is much more convenient for any welder to operate with a compact and mobile device than with a heavy iron transformer. The subject of this article, however, will be precisely modern welding inverters.

We will try to evaluate many advantages and some of the few disadvantages of welding inverters, consider their various options, and in the end we will compare the advantages and disadvantages so that even someone who is just thinking about purchasing a welding inverter can confidently come to a decision on its purchase.

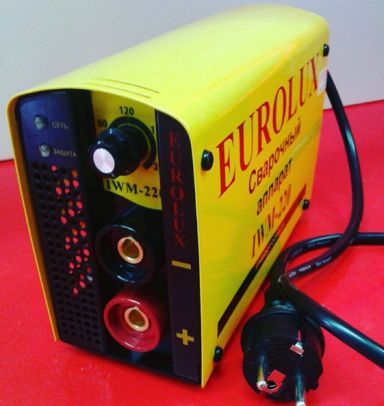

What is a welding inverter today? First of all, it is a compact semiconductor welding machine equipped with all types of shields and equipped with many options that facilitate the work of the welder, even if he is new to the profession.

Protection against sticking of the electrode, easy ignition of the arc, protection against overheating, etc. All these possibilities are opened thanks to the pulsed semiconductor technology implemented in modern welding inverters.

Unlike traditional welding transformers operating directly from the network, welding inverters use the principle of a high-frequency pulse converter (half-bridge, bridge, oblique bridge, chopper) in their work.

Mains voltage 220-240 volts with a frequency of 50 Hz is first converted to a direct voltage of 310 volts or more (simply by rectification or active conversion according to the PFC method), then this constant voltage is used for high-frequency energy conversion using a pulse transformer or inductor on a ferrite, the frequency here can in principle reach 200 kHz or more.

Thanks to high-frequency conversion, the size and weight of the device has become much smaller, there is no transformer iron, and ferrite is used as magnetic circuits of inductive elements.

Switching in the process of high-frequency conversion is carried out by semiconductor switches - field or IGBTs, the benefit is that the component base has expanded significantly today, the parameters of the keys are improving year after year - the resistance in the open state becomes less, the permissible current is more. To control the semiconductor keys, a driver is used, which in turn is controlled by a microcontroller.

Resonant circuits with switching at zero current have the highest efficiency, allowing to minimize heating losses of semiconductor switches. Powerful high-speed diodes or a synchronous rectifier are responsible for the rectification of high-frequency alternating current. Of course, the heating of components is somehow present even in resonant circuits, therefore, each inverter has radiators and fans for the cooling system plus an automatic overheat protection system.

So let's finally take a closer look at the advantages and disadvantages of welding inverters. First, consider the merits.

Testing the most common welding inverters on video:

Advantages of welding inverters

Efficiency

The efficiency of the welding inverter can reach 95% and higher, and the power factor approaches 0.9 and even unity. Inductive losses are simply absent due to the high-frequency pulse converter on semiconductors, which is unlikely to be achieved with a conventional welding transformer.

A high-frequency pulse converter operating at a frequency of 25 to 200 kHz effectively lowers the voltage and automatically turns off during breaks in operation, that is, electricity is not wasted.The cooling system works independently of the power circuit, has its own power supply, and during the welding process or during breaks does its job.

Power surges do not interfere with operation

The high-frequency converter inside the inverter automatically adjusts to the input voltage without affecting the output parameters. Even if the voltage in the network drops to 165 volts (depending on the model, the boundary voltage may be different), the inverter will continue to work, giving the required welding current, which is set by the welder manually before starting work. In the event that the voltage drops unacceptably low, the protection will trip and the inverter will automatically shut down, preventing overload of the input current.

Precise manual adjustment of welding current

The welding current parameters are set by the welder, just turn the knob on the front panel of the device, and the current for any electrode will be precisely set for the upcoming work. 40-60 amperes for 2 mm electrode, 160 amperes for 4 mm, and finally 220-250 amperes for 6 mm electrode. If you need more, there are inverters for current up to 500 A, but they are both more expensive and heavier.

For example, inverters for current up to 250 amperes are popular for domestic needs, and this is usually enough. Precise manual adjustment of the current allows you to achieve high quality weld, and at the same time eliminates undercooking or overcooking.

Any electrodes

For welding, you can use electrodes of both alternating and direct current for products made of cast iron or non-ferrous metal. It is also possible to perform argon-arc welding using a non-consumable electrode, since the inverter can regulate electric current over a wide range.

All kinds of protections

Precise electronic control allows you to implement all types of protection in the welding inverter, this is a typical set, but when choosing an inverter, you need to pay attention to exactly which protections are implemented in it.

Anti-sticking (anti-sticking function) - if the electrode is firmly stuck, the inverter will automatically turn off for a while so that the welder can tear off the stuck electrode, then the power resumes.

Short-circuit protection ("arc force" function) - the inverter generates a series of powerful pulses to melt a frozen drop. Finally, thermal protection - when the semiconductor switches are overheated, the inverter will turn off the output current so that the radiators are properly cooled.

Quick easy ignition

The "hot start" function will allow you to easily set the arc on fire, it is enough for the welder to simply strike the electrode on the part. The function is implemented by briefly supplying an auxiliary current pulse before starting work to facilitate ignition of the arc.

Light weight, mobility, comfort

An inverter with a total power of 8 kW today weighs less than 5 kg. Imagine how much the transformer weighs, with an overall power of 8 kW - more than 40 kg. The welding inverter is 10 or more times lighter than the welding transformer with the same power consumption. It is convenient to hang such an inverter on your shoulder while working on the stairs, simply using the belt that comes with the kit.

It can be safely put on building structures like scaffolding, and not be afraid that it will fall or damage the forests. In the end, with an inverter, you can climb anywhere and cook in any position, which is why welding inverters are so popular among summer residents, who immediately appreciated the charm of lightness and mobility.

Even a novice can easily cope.

If a person learns to cook for the first time, then he will probably pat a lot of nerves both for himself and for his mentor, if an ordinary iron transformer is used during training. With a welding inverter, training will go faster, because the "hot start", "arc force" and "anti sticking" functions will help a beginner overcome the typical difficulties of electric arc welding.

Even the wives of some summer residents are showing interest in such progressive welding machines, more like some kind of household appliance than the welding equipment of past years.

Disadvantages of welding inverters

Now let's talk about the disadvantages of welding inverters, they still exist, since they are considered to be such.

Price

For some reason, it is believed that the price of a welding inverter is a drawback. If you look at the prices of welding inverters, you really will find that this is by no means a penny. But the inverter costs exactly that much, because semiconductors, pulse transformers, condensers, controller boards, fans, radiators, the case in the end - all this is not free.

Yes, you have to pay this price, the more reliable and high-quality inverter made from high-quality components can not be cheap, in no case should be stingy when choosing a welding inverter.

Requires care

Due to the fact that the inverter contains printed circuit boards and small power components, in comparison with a large heavy transformer, pollution is dangerous here, even dust pollution, and moisture is especially dangerous. The inverter must be regularly cleaned of dust from the inside and protected from moisture. In frosts, especially below -15 ° C, it is better not to use the inverter.

If for some reason the inverter fails, then the repair will not be cheap, because high-quality components are always expensive (especially power components such as IGBTs and powerful high-speed diodes), and often you need to change expensive modules. It’s better not to lead to malfunctions, and to do only preventive maintenance, for example blowing with compressed air.

We hope that our article was useful for you, and now you can more responsibly and pragmatically approach the decision to purchase a welding inverter, weighing all the pros and cons.

See also at e.imadeself.com

: