Categories: Featured Articles » Sharing experience

Number of views: 51049

Comments on the article: 5

How to rewind LATR with your own hands at home

In the laboratory stands of my college, laboratory autotransformers (LATRs) regularly fail. It so happened that through trial and error I was able to master the technology of their repair. At the moment, I have managed to repair already three laboratory autotransformers, and I was rewinding LATRs in my dormitory room. I would be glad if the technology for rewinding LATRs described here is useful to someone. Yes, this is my first article, so do not judge strictly :-)

In the laboratory stands of my college, laboratory autotransformers (LATRs) regularly fail. It so happened that through trial and error I was able to master the technology of their repair. At the moment, I have managed to repair already three laboratory autotransformers, and I was rewinding LATRs in my dormitory room. I would be glad if the technology for rewinding LATRs described here is useful to someone. Yes, this is my first article, so do not judge strictly :-)

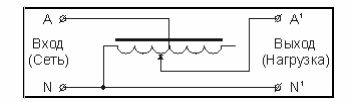

To begin with, a short course of the LATR device (see figure).

LATR has two windings connected in series. Mains voltage is applied to the primary winding (this must be taken into account when rewinding). The secondary winding is connected to the primary. It is designed for voltages from 0-240 V. Voltage is applied to terminals A and N in the magnetic circuit. A magnetic flux is created which induces current from the terminals A1 and N.

To begin with, you need to determine the diameter of the wire. This can be done with a caliper. To do this, you must first measure the diameter of the native wire, and then proceeding from this, look for a suitable wire for us. You can take a piece of the old wire and then compare it with the desired sample.

Then you need to determine the length of the wire. This can be done using the usual mathematical expression: L = l turn × W1,2 cm,

where L is the required wire length (in centimeters), l coil is the length of one turn; W1,2 - the number of turns of the secondary and primary winding.

Next, we determine the required number of turns necessary for the stable operation of the transformer. There are two possible options:

1) Calculation of the number of turns according to the formulas. This method is quite simple, but it is very likely to make an error, for example, in calculations or in measurements of the magnetic circuit window area. This method is given below:

- we find the power of the autotransformer: P = U × I,

where U is the output voltage, I is the maximum load current (usually written in LATR).

- the overall power is found: Рг = 1.9 * Sc * S,

where 1.9 is the drive coefficient for toroidal transformers.

- the required number of turns per 1 volt:

K = 35 / Sc, where 35 is the drive coefficient for toroidal transformers.

- determine the number of turns; W1 = U1 * K

- determine the dimensions of the core: Sс = ((Dc-dc) / 2) × h, So = πxd2 / 4,

where Sc is the transformer core area; So is the area of the window.

2) The second option is quite laborious, but reliable (when rewinding LATRs, I used this method). This method of determining the number of turns is that you need to rewind the old winding and at the same time count the number of turns. For him it is necessary: a leaf and a pen in order not to stray, a coil or a piece of wood to wind the old winding there, as well as steel nerves and patience, so as not to throw it out the window after a hundred counted turns.

After that, we rest and relax after the work done, because then we need maximum attention and patience. When you relax, we begin to prepare the workplace. It is desirable that it be well lit and that you can put all the necessary items, such as a desk with a lamp or a chair in a room with good lighting.

For the convenience of rewinding, it is better to wind the new wire first on a wooden blank as shown in the picture:

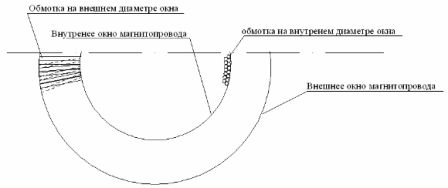

The fundamental difference is how the wire is settled, there is no window on the inner diameter. But in order to lay the desired number of turns, it is necessary to wind the first turn to it tightly, then wind the second turn, and lay the third turn on the top between the first and second and repeat until we wind the desired number of turns on a voltage of 220V.After that, we draw the output of the clamp of the network and from this output we house the secondary winding. On the outer diameter of the magnetic circuit window, all turns must be laid one after the other one after another as shown in the figure.

After the rewinding is completed, the winding must be impregnated with varnish to improve the insulating properties and to fix the wound wire in its place. Since a lot of varnish is not required here, you can use any temperature resistant up to 105 aboutC. After impregnation with varnish, the autotransformer is left to dry for a couple of hours. For a better effect, you can put it in a warm place. To leave the room where the work was done and it is very advisable to open the window for ventilation.

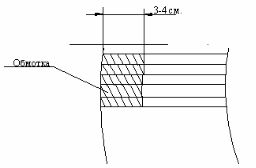

After drying, you need to make a track to relieve tension. This can be done with a knife or sanding paper. We make the track from the outer window to the inner length of about 3 cm (shown in the figure below).

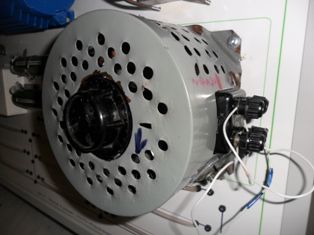

Next, we collect an autotransformer. When we install the bottom cover, you can check the windings with a tester - between the winding and the casing and between the beginning and end of the winding.

You can check the autotransformer by connecting it to the network. This is best done using a surge protector. First we test at idle. If after switching on the filter there were no explosions or short circuits, then the autotransformer was rewound successfully. After that, you can slowly turn the switch knob while the tester measures the readings from the terminals. If autotransformer started to hum (a small buzz may be allowed) and bask, this means that you made a mistake with the number of turns.

After that, you can turn it on under load and observe the transformer for 15 minutes. Then disconnect and check the temperature of the winding. If it is not very hot, then LATR is ready for work.

Anton Romashov, student of UO "GGPK" for the site https://e.imadeself.com/en

See also at e.imadeself.com

: