Categories: Featured Articles » Electrician at home

Number of views: 108369

Comments on the article: 11

Wiring requirements in an apartment and a house

Everyone who lives in a private house or apartment, sooner or later make repairs. This is especially true of the old housing stock. And every normal person begins to plan repair work - what needs to be done in the first place, and what can wait.

A so-called construction schedule is drawn up. You begin to ring up your acquaintances in search of normal craftsmen, repair is not done every day.

At the initial stage of construction-repair, as a rule, all installation work on plumbing and electrical work is carried out. Here we will consider the electrical part of the work in more detail, since, on how well it will be done electrician in your house, largely depends on the final result of the entire repair.

In order for everything to work properly in the house, apartment, it is necessary to observe during the electrical installation process wiring requirements in the house, apartment. Depending on the type of room, on the material through which the wires are conducted, the requirements for wiring are different.

We will not dwell on production facilities with aggressive environments, we will only consider residential wiring requirements, that is, in our apartments and houses.

So, the most stringent requirements for laying wires are presented to rooms made of wood. Wires laid on a wooden surface must be enclosed in metal pipes or in ducts that do not support combustion. The inner surface of the pipes must be painted.

Something like the sound of the requirements for laying wires in official papers. But there are many nuances during work. For example, a wooden surface is not always left open, it is often plastered. In this case, a strip of asbestos fabric can be placed under the wires. The edges should protrude at least 1 cm on each side of the wire. A layer of plaster on top of the wires, at least 1 cm.

Something like the sound of the requirements for laying wires in official papers. But there are many nuances during work. For example, a wooden surface is not always left open, it is often plastered. In this case, a strip of asbestos fabric can be placed under the wires. The edges should protrude at least 1 cm on each side of the wire. A layer of plaster on top of the wires, at least 1 cm.

Recently, especially for the installation of electrical wiring on wooden surfaces, they began to produce plastic pipes that do not support combustion, and component parts for installation are dose boxes, switches, sockets, fasteners. In addition to fire safety, this type has a fairly attractive appearance.

When mounting wires on concrete walls, bricks, etc., that is, on surfaces that do not support combustion, the requirements are less stringent in terms of fire safety. But there are other requirements for wiring. So, all wires must be laid strictly vertically and horizontally. The distance from the ceiling is 200-250mm. A layer of plaster or other finishing material is not less than 10-15 mm.

As for the wires. Many electricians, in recent years, use various brands of wires that are not intended for the installation of electrical wiring.

As for the wires. Many electricians, in recent years, use various brands of wires that are not intended for the installation of electrical wiring.

For example, many lay wires of the ShVVP and PVS brands. If you read the description of these wires, it clearly states that the ball screw is a cord designed to connect various equipment used at home and in office buildings.

The scope of the PVA is approximately the same as the ball screw, but the insulation of the PVA is more resistant to mechanical damage. It is recommended to use PVA for use as extension cords for various equipment and devices - lawn mowers, drills, etc.

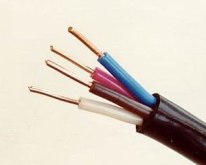

For stationary installation of electrical wiring in apartments, houses, wires intended for this should be used. It is for these purposes that it is recommended to use cables of brands VVG, VVGNG, GDP1, GDP2, etc. Number of cores in these products from two to five. They are designed for voltages up to 600 V.

For stationary installation of electrical wiring in apartments, houses, wires intended for this should be used. It is for these purposes that it is recommended to use cables of brands VVG, VVGNG, GDP1, GDP2, etc. Number of cores in these products from two to five. They are designed for voltages up to 600 V.

Many recommend using PUNP and PUGNP for stationary installation of electrical wiring.Although the passport for these wires gives recommendations for use as stationary wiring, we would recommend that you refrain from using this wire. The fact is that the insulation in the wires of these brands, with a little heating, loses its properties. As a result, there is a high probability that a short circuit will occur (short circuit). The consequences are not worth talking about.

For linear lighting groups, it is recommended to use wires 3 * 1.5mm / sq. The number 3 shows the number of cores. Why three, because two is enough. To prevent electric shock, that is, for safety reasons, manufacturers of all electrical appliances, which undoubtedly include luminaires, recommend grounding metal parts.

For linear lighting groups, it is recommended to use wires 3 * 1.5mm / sq. The number 3 shows the number of cores. Why three, because two is enough. To prevent electric shock, that is, for safety reasons, manufacturers of all electrical appliances, which undoubtedly include luminaires, recommend grounding metal parts.

For outlet groups, apply wires and cables with a cross section of 2.5 mm / sq. The number of cores should also be equal to three. Phase, zero, earth.

In case of application stranded wires, all ends must be pressed with special tips or soldered. In any case, the selection and installation of electrical wires must be performed by a qualified specialist.

Sergey Seromashenko

See also at e.imadeself.com

: