Categories: Featured Articles » Electrician at home

Number of views: 347,582

Comments on the article: 50

Safe wiring in a wooden house: not a myth, but reality

How to make safe wiring in a wooden house?

The most popular material for the construction of country houses was and remains a tree. Which, with all its numerous advantages, has one serious drawback, is, as firemen say, "combustible material."

The most popular material for the construction of country houses was and remains a tree. Which, with all its numerous advantages, has one serious drawback, is, as firemen say, "combustible material."

Fire statistics indicate that more than half of fires in wooden houses occur due to faulty wiring. In practice, the main cause of malfunctions and the subsequent short circuit is most often a violation of the integrity of the insulation of the wires in the wiring. As a rule, this occurs either due to the increased load on the wires or due to mechanical damage to the insulation.

Why is this happening?

Most homegrown "handymen", in order to save time, effort and money, are laying hidden electrical wiring on wooden foundations, boldly hiding it behind the ceiling sheathing, under the wall cladding, behind the plinth, into the voids of the floors and explaining to the “unreasonable” client what to do.

Remember! Install hidden electrical wiring in wooden houses using a corrugated PVC pipe, plastic box NOT!

Why?

In fact, there are several reasons. Below we will consider two of the most typical situations that arise when operating electrical wiring in a wooden house.

At first. In the process of laying the cable, an electrician may slightly violate the insulation of the wires, and control electrical measurements of damage may not be recorded.

However, when all the necessary electrical equipment is connected, the wiring begins to function in maximum load mode. Naturally, such an operation, which causes increased heating of the cable or wire, inevitably weakens the insulation, which causes a short circuit in the wiring.

Sufficiently thin walls of plastic pipes and PVC boxes are unable to withstand a short circuit without burning, therefore, a short circuit, alas, will inevitably result in a fire.

Secondly. Hidden electrical wiring using a corrugated pipe or PVC duct, laid in the voids of wooden walls, floors and floors, is an object of increased attention from the side of rodents that are frequent in wooden houses, trying to “try their best” in the details of your communications.

For mice, and even more so for rats, it will not be difficult to cut a sufficiently thin pipe or PVC box, exposing the wire strands, resulting in a short circuit in the hidden wiring.

The situation is aggravated by the fact that in the voids of the walls and ceilings of wooden houses over time, a huge amount of wood dust accumulates. As a result, the slightest spark leads to a fire. The worst thing is that it is practically impossible to immediately determine the place of ignition and to liquidate it, since the combustion process that occurs BEYOND walls and ceilings is hidden from view. Therefore, even a flood of water and foam all around, you still can not put out a fire quickly.

Can these problems be avoided?

At first glance, if you lay the wiring in a wooden house according to the requirements of SNiP, PES, there will be no problems. However, in reality, not everything is so simple. First of all, because the requirements of the PUE regarding the installation of electrical wiring in wooden buildings are extremely stringent. By the way, it is precisely the rigidity of standards that most often forces home-grown electricians to violate them.

Nevertheless, laying fireproof wiring in a wooden house is a feasible event, and you can choose which wiring to use.

The table below shows the types of wiring and methods for laying wires and cables according to fire safety conditions.

Let us consider in more detail all types of fireproof wiring in a wooden house.

Concealed wiring

Although most competent sources on this subject do not recommend installation of hidden wiring on combustible, in our case, wooden structures, however, with subject to fire safety and the absence of financial problems, such a posting can be done.

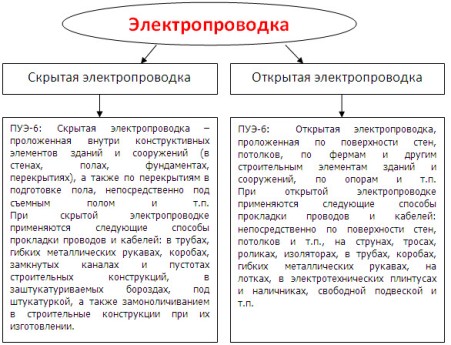

Below we provide a regulatory document (PEU-6) in its part regarding the laying of hidden wiring indoors.

In fact, methods of fireproof laying hidden wiring in a wooden house just two.

One of them is laying hidden electrical wiring with metal sleeve (pipe). The main advantage of this method is that in case of fire metal pipe will protect adjacent structures from fire.

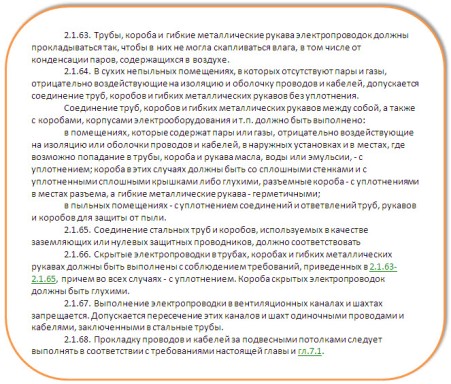

When using this method of wiring, you will need to observe several stringent conditions: to protect the walls of the pipe from corrosion, it must be painted or galvanized from the inside. To protect the cable insulation from sharp edges resulting from pipe cutting, special plastic plugs must be put on their ends. Plus, for such a wiring you will need to drill recesses in the thickness of the walls in the form of channels into which, in fact, metal pipes are then laid.

The best option for this type of wiring is copper pipes. Due to the fact that copper pipes bend quite easily and can be laid without special tools, wiring is at least somewhat simplified. However, for simplicity and convenience you will have to pay a high, literally, price - copper pipes are very expensive.

In accordance with GOST R 50571.15–97 (IEC 364 5 52 93): Clause 522.3.2, pipes should be laid with a slight slope to allow condensate to flow out. But be prepared for the fact that in practice it is extremely difficult, if not impossible, to check the quality of installation of metal pipes, the same angle of inclination or the tightness of the joints.

The second way to lay hidden electrical wiring in a wooden structure is on a layer of plaster (sketch) at least 10 mm thick on all sides.

Way like simple, however, when using it, the question arises: how to comply with PES standards regarding wiring interchangeability. Alternatively, you can monolith power cable in plaster, having previously packed it in a corrugation. Formally, of course, the PES standards will be met, but in fact it will be impossible to pull the hard wire.

Moreover, no specialist will be able to predict how stucco will behave on wooden surfaces after some time. Will the cracks go? Will she start to fall off? Not to mention the fact that on beautiful wooden surfaces a thick layer of cement mortar will look, at least, strange.

It should be emphasized that both of these methods are quite expensive both in terms of money, and in efforts, and in time. Plus, they require wiring planning at the construction stage.

Open wiring

- Wiring in electrical corrugated pipe

This method involves pulling the cable into a flexible corrugated pipe made of special plastic that does not support combustion. Two or more cables can be placed in one pipe.

The disadvantages of this method include, first of all, its unaesthetics - you are unlikely to like the prospect of “decorating” your house with several rows of corrugated pipes. Given the number of electrical appliances in a modern house, such rows can be 5-7! In addition, since the corrugated pipe with the cable stretched into it is almost impossible to lay straight, “along the string”, all its bends and sagging will also not add charm to your home.

One more minus: the corrugated pipe is an excellent “dust collector”, it is very difficult to remove the accumulated dust from it.

- Wiring in electrical boxes (cable channels)

With this method, the cable is laid in special boxes (cable channels) from flame retardant plastic and close with snap-on covers.

The main problem when using this method is associated with the inevitable shrinkage of a wooden house. On average, it is 1 cm per 1 m of the height of the house, and these values are given for houses made of high-quality glued timber, the shrinkage of which is minimal. In practice, this means that shrinkage of three centimeters (for a typical two-story house) will squeeze all the boxes, the covers will fly off, the boxes themselves will crack. As a result - the wiring will have to be redone!

Secondly, in order to accurately and evenly install plastic boxes, a certain skill and dexterity will be required. Add problems with accessories here - alas, manufacturers offer a rather meager assortment of turns, angles, plugs, joints, without which it is almost impossible to accurately install cable channels.

Another significant drawback of wiring in cable channels is its boring, office look.

The advantages of this method include its cheapness, minimal labor and the ability to easily make any changes in the future.

- Open cable wiring

Last, we will consider the most optimal of all methods of laying electrical wiring in a wooden house - open cable wiring.

Naturally, when using an unprotected open cable, talking about the aesthetics of the room is also not necessary. Not only does the cable itself in conventional insulation (for example, the most common PUNP) look rather dull, it will still be necessary to install a gasket made of asbestos or metal, protruding from all sides by at least 10 cm.

However, there is another way. This is the so-called retro wiring on insulators. Its main strengths are the opportunity compliance with all necessary safety requirements, a plus, original, extremely popular Recently, retro style interior design.

You will learn more about installing such wiring in our next article.

Company LLC "Salvador"

Electrician in a wooden house on the video:

See also at e.imadeself.com

: