Categories: Electrician Secrets, Automata and RCD

Number of views: 33862

Comments on the article: 8

Comparison of circuit breaker designs

In order to equip their customers with high-quality electrical equipment, electricians must know which circuit breakers of which companies should be preferred. And in order to make a conclusion about the quality of the machine, it is important to monitor operational malfunctions and know their design.

In order to equip their customers with high-quality electrical equipment, electricians must know which circuit breakers of which companies should be preferred. And in order to make a conclusion about the quality of the machine, it is important to monitor operational malfunctions and know their design.

For this, the designs of automatic machines of three different companies were compared: ABB (Germany), IEK (Russia) and E.NEXT (China).

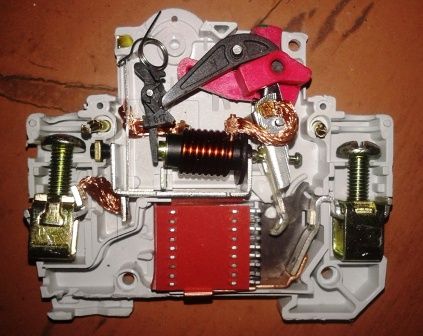

Structurally, all three machines were very similar and had all the necessary elements, such as: an arcing chamber, a bimetallic plate, a coil. Only by looking closely, it was possible to see the difference.

At the first stage was disassembled ABV circuit breakermade in Germany. The products of this manufacturer are considered one of the best in the world.

About 30 of these devices were replaced in the electrical panel of a large supermarket, due to their strong heating. Note that these switches worked for about 12 years. At the same time, twice a day, the store’s security turned on and off the lighting of the hall, that is, the switch was switched at rated load.

After the autopsy, a burned-in contact group was immediately visible, which in all likelihood led to overheating.

Please note that all parts of the machine were copper-plated, starting from the terminals.

In the second stage was disassembled IEK machinemade in Russia.

This unit was dismantled after the first day of operation, due to the fact that it made a crack during operation. Interestingly, the second machine of the same company, installed next, also popped. The volume of the cod increased with the current load on the machine. The Eaton circuit breaker was installed for the third time, and the Russian circuit breakers went for disassembly.

At autopsy, the automatic platoon mechanism immediately strikes the eye, which is much simpler than in the first case. But as it turned out easier, it does not always mean better. After the first day of work, a burned contact group is visible. The probable cause was the insufficient pressure force of the movable contact to the motionless. In addition, the movable and fixed contacts are made of ordinary metal.

In the third stage was disassembled E.NEXT machine gunconsidered one of the most inexpensive.

Immediately surprised that, despite the low cost, the machine was going to 6 rivets like the German counterpart. While the Russian apparatus had 4 rivets.

The platoon mechanism and the contact group were fundamentally no different from the Russian machine gun.

The terminals of all three machines were structurally identical. But it is worth noting that in the Russian and Chinese circuit breakers, the thread on the terminal screws is very often broken. In some cases, the screw is not threaded.

Conclusions:

1. The studied machines of all three firms had all the necessary components of a modern circuit breaker. So, they will be able to perform their functions.

2. The main constructive drawback of the Russian and Chinese-made machines was the platoon mechanism, which in fact is a two-lever structure.

The lever of the German automatic machine feels easier cocking, however, this is not connected with the clamping force of the contact group.

3. An equally serious drawback of cheaper machines is that their conductors are made of ordinary metal. Manufacturers do not cover them with copper plating, apparently, so as not to increase the cost of the product.

As a result, copper is soldered to steel, which unambiguously leads to transient resistance.

In a German machine, the moving contact is made of pure copper, and the remaining conductive parts are copper-plated.

See also on this topic:How to choose a circuit breaker for an apartment, house, garage

See also at e.imadeself.com

: