Categories: Featured Articles » Novice electricians

Number of views: 7561

Comments on the article: 1

Electromagnetic actuators: types and applications

In production and in everyday life, automation is actively used. For this, actuators of various types are used, hydraulic, pneumatic and electric. Such devices include, disable, change the mode of operation of mechanisms, systems and devices. In this article we will look at some electromagnetic actuators.

Actuators

To propel various mechanisms using electric motors and electromagnetic actuators. For example, electric motors are used for automatic or semi-automatic control of valves, the so-called shutoff valves on pipelines, like gas, pneumatic, water supply and other.

The principle of operation of the electromagnetic actuator is to perform work with a magnetic field to move the core associated with actuators.

General device

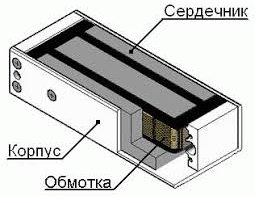

If we consider electromagnetic actuators in a general form, then it consists of:

1. Coils.

2. The magnetic core.

3. Related working mechanisms and systems.

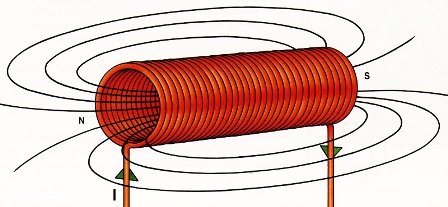

Under the coil is meant an electromagnetic device - a coil wound on a mandrel with a copper wire, inside of which there is a core. Another name is a solenoid. Same device has a relay.

Outside the solenoid, a magnetic circuit can be located, the so-called ferromagnetic yoke, it is needed to amplify and direct magnetic forces.

When an electric current flows through the coil, a magnetic field appears, the metal elements of the executive part (anchor or core) are drawn in and certain work is performed. Thus, the electric current is converted into translational motion, and such actuators can be called translational electric drive.

It is worth noting that the industry manufactures both devices for working in DC and AC circuits. In principle, electromagnetic actuators, which contain rectifiers in their design, are widely used in AC circuits. This is due to the fact that DC electromagnets develop more traction and have greater stability at the same dimensions as an AC electromagnet, and are also cheaper to manufacture.

It is also worth noting that most representatives of the electromagnetic drive are limited to two end positions of the core, such as “on” / “off”.

Let's look at where such actuators are found, start with what is most often found in everyday life, then consider industrial designs.

ICE starter solenoid relay

In cars, a starter is used to start the engine - a powerful DC electric drive. There are two tasks that need to be solved for its operation:

1. A starter is a rather powerful electric motor, its power, depending on the engine being launched, can vary from 0.5 kW on scooters and light motorcycles to 10 kW on special equipment with diesel engines. Such power is needed to create enough moment to crank the engine crankshaft.

This raises the problem of passing a current of this magnitude, for this you can use a relay, but in reality everything is done a little differently, later we will consider this issue.

2. The starter drives the ICE by rotating the flywheel, on which the crown is worn - a gear ring. The starter is connected to the flywheel using a bendix (this is an overrunning clutch), it is needed in order to prevent the transmission of torque from the engine to the starter shaft.

When you turn on the starter power circuit, the bendix connects to the teeth of the flywheel crown and starts to rotate it when the engine starts and you turn off the starter circuit - it returns to its original position.

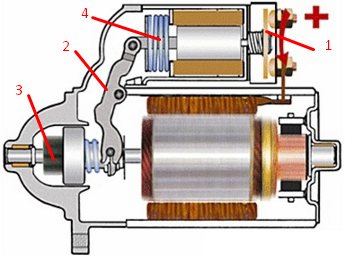

To solve these two problems with one device, a pull-up relay is installed on the starter. Firstly, this relay closes the power contacts (1), through which the starting and operating currents of the starter flow. Secondly, a special rod (2) is connected to the moving part of the relay, which pushes the bendix (3) and, using the spring (4), returns it back.

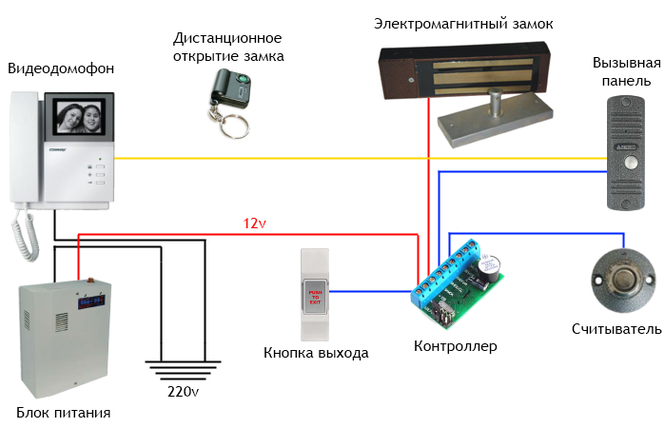

Electromagnetic lock

An electromagnetic lock allows you to implement various security systems, automatic unlocking of doors when approaching the owner or when reading the value of the RFID tag, NFC or other communication and identification technologies.

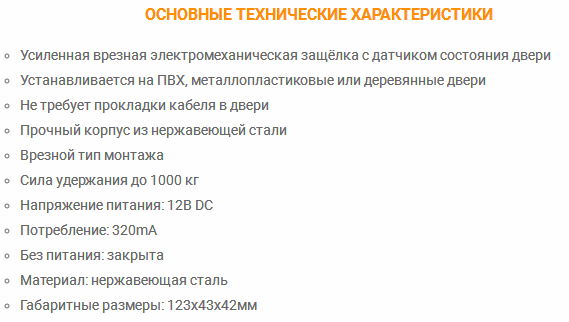

For example, consider the characteristics of one of the options. This is an electromechanical latch.

The technical characteristics are quite interesting, it can withstand a force of up to 1000 kg, with a current consumption of 0.32A and a voltage of 12V, this is slightly more than 4W of power. Such locks are useful for organizing ACS or smart home projects.

There are other options for electromagnetic locks that work on the same principle.

They are used together with intercoms at the entrance doors of the entrances.

Solenoid valve

Valves are installed in the pipelines to control the passage of the working medium (gas or liquid). They are normally open (they allow liquid / gas to pass through when voltage is not supplied) and normally closed (they pass only when voltage is applied).

In this case, normally-closed valves are often structurally made with elastic fixation, which avoids damage to the pipeline during a sharp pressure change, i.e. it slightly passes the working medium to compensate for a sharp change in pressure.

Moreover, in high pressure pipelines, the electromagnetic valve controls the opening not of the main pipeline, but of the pneumatic or hydraulic system, which unlocks the main power part of the shutoff valves.

Thus, it is possible to arrange the degree of opening of the valve or valve. The implementation is quite simple - the alternate opening of the feed into the chamber direct or reverse control substance (pneumatics or hydraulics).

According to the principle of action, they are distinguished:

-

direct action, triggered by zero differential pressure;

-

pilot (indirect action), which operate with a minimum pressure drop.

And also on:

-

locking (2/2 way);

-

distributing three-way (3/2 way);

-

switching valves (2/3 way).

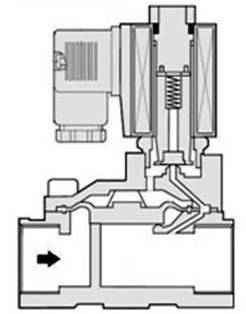

Pilot Solenoid Valve

Below is a diagram of a normally closed valve.

When coil power is not supplied, the valve remains in the closed position. A piston or diaphragm is pressed firmly against its seat under spring pressure.

When the power is connected to the coil, the forces that arise counteract the spring and the valve opens. Please note that the description omits a number of details that are not related to electricity.

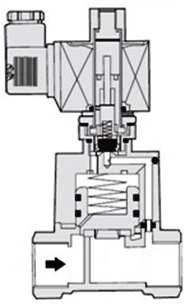

Below is a normally open valve.

When voltage is not supplied to the coil, it is open, and when you apply voltage, it closes, this one, like the previous valve, needs to hold the supply voltage on the coil in order to maintain it.

In addition to power, you also need to remember that they only work when the pressure differential. It can be used in heating, water supply, pneumatic systems.

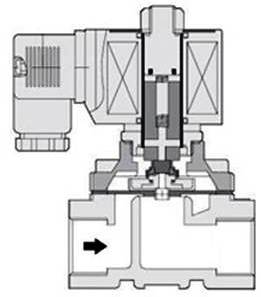

Direct acting solenoid valve

The main difference is that to open / close it does not need a pressure drop before and after the valve. This means that they can be used both in pipelines with and without pressure - draining liquids from containers, receivers. They usually have too little or no pressure.

Bistable valve

Another name for bistable valve is pulse.To hold in the open / closed state, holding the control voltage is not required. To switch states, a voltage pulse of a certain polarity is applied. They work in DC circuits.

These valves require a pressure differential.

An electromagnetic or solenoid valve is a reliable pipeline valve with a long service life (about a million switching operations).

In addition, they are distinguished by high speed (30-500 ms, depending on the diameter), which cannot be provided by valves driven by an electric motor. In addition, it does not require such maintenance and regular adjustment, installation limit switches like the same gate valves.

Electromagnet

Electromagnets are widely used in metallurgy, manufacturing and landfills. This is a great option for lifting and transporting scrap metal and metal products.

There are such types of electromagnets:

-

neutral electromagnets - work from a direct current;

-

polarized electromagnets, work in the presence of two independent magnetic fluxes - working and polarizing;

-

AC electromagnet - pulsating magnetic flux from zero to maximum, vibration of the armature is characteristic.

Like some types of electric motors, the inclusion of windings differs:

-

sequential when the windings are made with a thick wire with a small number of turns;

-

parallel when the windings are thin wire and a large number of turns.

So the mode of operation:

-

Durable;

-

Short-term;

-

Intermittent.

Conclusion

An electromagnetic drive is a quick and cheap option for actuators. Also, for the most part, it has greater durability than an electric motor drive, due to the lack of rotating working parts, gearboxes.

See also at e.imadeself.com

: