Categories: Featured Articles » Novice electricians

Number of views: 87029

Comments on the article: 5

Polar and non-polar capacitors - what is the difference

All kinds of types of capacitorsused today almost everywhere in electronics and electrical engineering, they contain various substances as dielectrics. However, specifically electrolytic capacitors, in particular also tantalum and polymer, then for them, when included in the scheme, it is important to strictly observe the polarity. If such a capacitor is not included in the circuit correctly, then it will not be able to operate normally. These capacitors are therefore called polar.

What is the fundamental difference between a polar capacitor and a non-polar one, why do some capacitors still care how to be included in the circuit, and the observance of polarity is fundamentally important for others? We’ll try to figure it out now.

The point here is that the manufacturing process of electrolytic capacitors is very different from, say, ceramic or polypropylene. If the last two both the plates and the dielectric are homogeneous with respect to each other, that is, there is no difference in the structure at the plate-dielectric interface on both sides of the dielectric, then the electrolytic capacitors (cylindrical aluminum, tantalum, polymer) have a difference in the structure of the dielectric transition -cladding on both sides of the dielectric: the anode and cathode differ in chemical composition and physical properties.

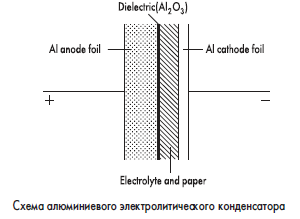

When an electrolytic aluminum capacitor is made, it is not just that they roll two identical foil covers laid with electrolyte-impregnated paper.

On the side of the anode plate (to which + is supplied) there is a layer of aluminum oxide deposited on the etched surface of the foil in a special way. The anode is designed to give electrons through an external circuit to the cathode in the process of charging a capacitor.

The negative lining (cathode) is simply aluminum foil; electrons come to it in the process of charge through an external circuit. The electrolyte here serves as a conductor of ions.

The situation is the same with tantalum capacitors, where tantalum powder is used as an anode, on which a tantalum pentoxide film is formed (the anode is connected with an oxide!), Bearing the function of a dielectric, then there is a layer of a semiconductor - manganese dioxide as an electrolyte, then a silver cathode, from which the electrons will leave during the discharge process.

Polymer electrolytic capacitors use a light conductive polymer as a cathode, but otherwise all processes are similar. The bottom line is the oxidation and reduction reactions, as in a battery. The anode is oxidized during the electrochemical discharge reaction, and the cathode is restored.

When the electrolytic capacitor is charged, there is an excess of electrons on its cathode, on the minus plate, reporting just the negative charge to this terminal, and on the anode - a lack of electrons, giving a positive charge, thus we get the potential difference.

If a charged electrolytic capacitor is shorted to an external circuit, then excess electrons will run from the negatively charged cathode to the positively charged anode, and the charge will be neutralized. In the electrolyte, positive ions move at this moment from the cathode to the anode.

If such a polar capacitor is not included in the circuit correctly, then the described reactions will not be able to proceed normally, and the capacitor will not work normally. Non-polar capacitors can work in any inclusion, since they have neither anode, nor cathode, nor electrolyte, and their plates interact with the dielectric in the same way, just like with the source.

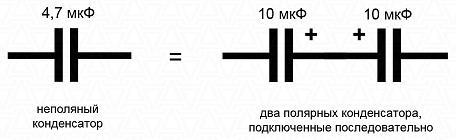

But what if at hand there are only polar electrolytic capacitors, but you need to carry out the inclusion of a capacitor in a current circuit with a changing polarity? There is one trick for this. It is necessary to take two identical polar electrolytic capacitors, and connect them together in series with the same terminals. You will get one non-polar capacitor from two polar, the capacitance of which will be 2 times less than each of its two components.

On this basis, by the way, non-polar electrolytic capacitors are made in which an oxide layer is present on both plates. For this reason, non-polar electrolytic capacitors are much larger than polar capacitors of a similar capacity. Based on this principle, non-polar electrolytic starting capacitors are also manufactured, designed to operate in alternating current circuits with a frequency of 50-60 Hz.

See also:Capacitors in electronic circuits

See also at e.imadeself.com

: