Categories: Practical Electronics, Home automation

Number of views: 113009

Comments on the article: 8

Automatic pump control in the country

The article describes a simple and reliable control circuit for an electric pump. Despite the extreme simplicity of the circuit, the device can operate in two modes: water lifting and drainage.

The article describes a simple and reliable control circuit for an electric pump. Despite the extreme simplicity of the circuit, the device can operate in two modes: water lifting and drainage.

At the cottage or in the farm without water it is simply impossible to do. As a rule, there is no centralized water supply in such remote places, so there are not so many ways to extract water. This is a well, well or open water. If there is electricity in the summer cottage, then the problem of water supply is best solved with the help of an electric pump.

In this case, the pump can operate either in the mode of filling the tank, or in the drainage mode - pumping water from the tank, well or well. In the first case, overflow is possible over the edge of the tank, and in the second case, the pump runs dry. For any pump, this mode is very harmful in that the cooling conditions worsen without water, and the motor may fail. Therefore, even in such simple cases, a pump control circuit is required.

For the device of country water supply at a certain elevation, it is desirable to establish a container into which water will be supplied by the pump. In the right places of the site and at home, water from the tank will be supplied using water pipes. In the summer will be provided automatic watering plants heated by the sun's water, and after working on the site, you can take a shower.

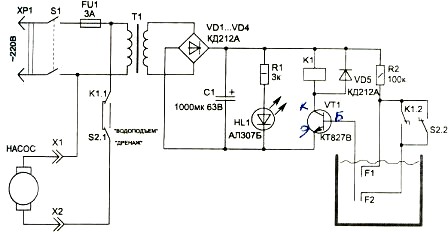

One of the possible options for the circuit is shown in Figure 1.

Figure 1. Garden pump control circuit.

The number of circuit parts is small, which allows you to assemble it by the method of surface mounting simply on a piece of plastic or even plywood, without developing a printed circuit board. Its reliability is very high, because with so many details there is simply nothing to break.

Switching on - switching off the pump is carried out by a normally-closed contact of relay K1.1. Switch S2 selects the operating mode (Water rise - Drain). In the diagram, the switch is in the “Water Lift” position.

The water level in the tank is monitored by sensors F1 and F2. The design of the sensors and the circuit itself is such that the tank body is not connected to anything, so electrochemical corrosion of the tank is completely excluded. Moreover, the tank can be made of plastic or wood, so it is possible to use even an ordinary wooden barrel.

The water level in the tank is monitored by sensors F1 and F2. The design of the sensors and the circuit itself is such that the tank body is not connected to anything, so electrochemical corrosion of the tank is completely excluded. Moreover, the tank can be made of plastic or wood, so it is possible to use even an ordinary wooden barrel.

Possible design of sensors. The sensor for automatic equalization of the pump can be made of two strips of insulating material that is not wetted by water. It can be plexiglass or fluoroplastic, and conductive plates are preferably made of stainless steel. Safety razor blades are very suitable for these purposes.

Another sensor option is just three rods with a diameter of about 4 - 6 mm, mounted on a common insulating base: the middle electrode is connected to the base of the transistor, and the other two are simply cut to the desired length, as in the schematic diagram.

When the power is turned on by switch S1, if the water level is lower than the sensor F1, the coil of relay K1 is de-energized, so the pump will start through the normally-closed contacts of relay K1.1. When the water rises to the upper level sensor F1, the transistor VT1 opens, which turns on the relay K1. Its normally closed contacts K1.1 will open and the pump will stop.

At the same time, the contacts of the relay K1.2 are closed, which will connect the lower-level electrode F2 to the base of the transistor VT1. Therefore, when the water level decreases below the sensor F1, the relay does not turn off (recall that the pump is started when the relay K1 is released), since the transistor is opened by the base current along the chain R2, K1.2 F2 and the relay K1 is kept on. Therefore, the pump does not start.

When the water level drops below the electrode F2, the base current will be interrupted, and the transistor VT1 will close and turn off the relay K1, the normally-closed contacts of which will start the pump. Next, the cycle will be repeated again. If the switch S2 is set to the right position according to the diagram, the pump will work in the drainage mode. In this case, one should take into account this circumstance: if it is a submersible type pump, in order to avoid dry running, its intake part should be below the low level sensor F2.

A few words about the details. The circuit is not critical to the types of parts used. As a transformer, any low-power transformer is suitable, for example, from three-program broadcast receivers or from Chinese DC adapters. In this case, the voltage across capacitor C1 must be at least 24 V.

A few words about the details. The circuit is not critical to the types of parts used. As a transformer, any low-power transformer is suitable, for example, from three-program broadcast receivers or from Chinese DC adapters. In this case, the voltage across capacitor C1 must be at least 24 V.

Instead of KD212A diodes, any one with a rectified current of about 1 A and a reverse voltage of at least 100 V is suitable. The VT1 transistor can be replaced by KT829 with any letter or by KT972A. capacitor C1 type K50-35 or imported.

LED HL1 indicates the device is connected to the network. It can be replaced with any red LED. The circuit uses a relay type TKE52POD, which can be replaced with any coil with a voltage of 24 V and with contacts that can withstand the current consumed by the pump.

A pump control device correctly assembled from serviceable parts, as a rule, does not need adjustment. But before installing it in the tank, it is better to check what is called on the table: instead of a pump, temporarily connect a light bulb of low power, and the electrodes can be imitated in a glass of water, or even without water.

To do this, turn on the circuit while the light should come on. Then close the electrode F2, - the bulb continues to light. Without breaking the electrode F2, close the electrode F1, and the light should go out.

After that, sequentially open the electrodes F1 and F2, - the bulb will go out only after the latter has been opened. If everything works this way, then you can safely connect the pump and use your own water pump.

Boris Aladyshkin

See also at e.imadeself.com

: