Categories: Featured Articles » Interesting electrical news

Number of views: 66847

Comments on the article: 6

Dry heater for storage water heaters

The popularity of electric storage water heaters (boilers) increases every day, which is not surprising when you consider the cost of hot water from a centralized water supply system.

The popularity of electric storage water heaters (boilers) increases every day, which is not surprising when you consider the cost of hot water from a centralized water supply system.

Cold water flowing into the boiler is heated to the desired temperature TENOM. TEN - tubular electric heater, which is a metal tube with a wire located inside, heating to high temperatures when an electric current passes through it. Between the walls of the tube and the wire there is dielectric sand, due to which the electrical safety of the product is significantly increased.

Simplified boiler represents a capacity with two tubes - for supplying cold water and withdrawing hot. Inside the tank is a heating element that heats the water.

Many people are very familiar with the white coating that appears on the electric kettle TEN, which must be cleaned or eliminated with citric acid. This coating is an insoluble calcium and magnesium salt falling out of the water when heated. The higher the temperature, the more active the deposition occurs, and in the hottest area.

The concept of “hard water” characterizes precisely the amount of calcium and magnesium. In hard water, soap foams poorly, and the precipitate in the kettle constantly boils when boiled. Almost all water from wells and boreholes is hard.

The concept of “hard water” characterizes precisely the amount of calcium and magnesium. In hard water, soap foams poorly, and the precipitate in the kettle constantly boils when boiled. Almost all water from wells and boreholes is hard.

At the heating heater of the boiler, the same process of salt deposition occurs. Over time, this layer becomes quite thick and significantly impairs the transfer of heat from the housing of the heater to the water, which means the cost of heating additional electricity.

In many cases, the amount of salts deposited is so great that it is almost impossible to disassemble a boiler for an audit. To solve this problem, there are several solutions - the use of cold water in the feed polyphosphate filters and magnesium rods built into boilers.

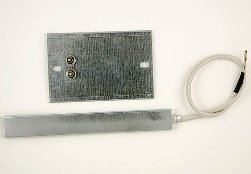

Appeared on the market a few years ago boilers with a new technological solution - dry heating elements. In them, the heater is located inside a metal glass flask, the walls of which are in contact with water.

Appeared on the market a few years ago boilers with a new technological solution - dry heating elements. In them, the heater is located inside a metal glass flask, the walls of which are in contact with water.

Dry heating elements are in the process of development, so at the moment there are many options for their execution:

- there is oil between the flask and the heating element. Since the thermal conductivity of the oil is higher than that of air, it saves energy spent on heating water,

- the flask with the heater is filled with quartz sand. With such a device, it is easier to replace the heater;

- the simplest design, when the heater is simply “hidden” in a flask. The most affordable, and replacing the heating element does not cause any difficulties.

When using the technology of dry heating elements, electrical safety is significantly increased, since there is no direct contact with water. When a heated wire burns out, in some cases it may come into contact with the tube walls and an electric potential (voltage) appears on the boiler and water. Though modern heating elements reliable enough and when burned out they simply stop working, however, there is a danger of electric shock.

Another advantage is the ease of replacing a failed heating element. In a boiler with a conventional (wet) heating element, replacing it requires draining the water, removing the boiler and difficulties with twisting it out of the housing. Often the amount of salts reaches a huge amount, and these growths do not allow to extract the heater from the boiler body.

Ceramic dry heater for boiler

Almost all manufacturers presented models of boilers with dry heating elements, which indicates the prospects of this area, and the constant reduction in cost makes the purchase of such a boiler the optimal solution.

See also at e.imadeself.com

: