Categories: Featured Articles » Interesting electrical news

Number of views: 76163

Comments on the article: 10

Polymer Solar Panels

Solar panels, although environmentally friendly, are also very expensive. Scientists have found an alternative to them - polymer solar panels. What it is is described in the article.

Solar panels, although environmentally friendly, are also very expensive. Scientists have found an alternative to them - polymer solar panels. What it is is described in the article.

A person, even a little interested in solar energy, is well aware of what solar battery - This is the combination of a large number of photocells mounted on any surface.

A solar cell is a semiconductor device that converts the energy of the sun into electric current. Solar cells of "traditional" solar cells are made of silicon. The manufacturing process for such batteries is complex and very expensive. Despite the fact that silicon is a very common element and that the earth's crust contains about 20% silicon, the process of converting source sand to high-purity silicon is very complicated and expensive.

In addition, sometimes there are problems with the disposal of waste photocells, since in addition to silicon, these photocells also contain cadmium. And finally, silicon photocells become very hot as they work. After which their performance begins to decline. Therefore, in addition to photocells, silicon batteries also require expensive cooling systems. See more about this here: How are solar panels arranged and work?. All this made scientists look for more effective methods for converting solar energy.

An alternative to silicon solar panels could be polymer solar panels. This is a new technology, and dozens of research institutes and firms around the world are working on its development. See also: New technologies. Conductive plastic

An alternative to silicon solar panels could be polymer solar panels. This is a new technology, and dozens of research institutes and firms around the world are working on its development. See also: New technologies. Conductive plastic

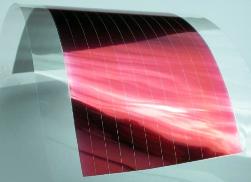

A polymer photocell is a film that consists of an active layer (polymer), aluminum electrodes, a flexible organic substrate and a protective layer. To create rolled polymer solar cells, individual film solar cells are combined.

The advantages of polymer solar cells compared to conventional crystalline: compactness, ease, flexibility. Such batteries are inexpensive to manufacture (expensive silicon is not used for their manufacture) and are environmentally friendly, since they have a less significant impact on the environment.

There is only one drawback - the efficiency of converting solar energy to polymer solar cells is still very low. This drawback limited the creation of such batteries at the level of prototype samples.

Currently, the highest efficiency of polymer solar cells managed to get Alan Heiger from the Center for Polymers and Organic Solids of the University of California at Santa Barbara (seven years ago he received the Nobel Prize in Chemistry for the discovery and development of conductive polymers) and Gwang Lee from the Korean Institute of Science and Technology in Gwangju.

Currently, the highest efficiency of polymer solar cells managed to get Alan Heiger from the Center for Polymers and Organic Solids of the University of California at Santa Barbara (seven years ago he received the Nobel Prize in Chemistry for the discovery and development of conductive polymers) and Gwang Lee from the Korean Institute of Science and Technology in Gwangju.

Their solar battery has an efficiency of 6.5% with an illumination of 0.2 watts per square centimeter. This is the highest level achieved for solar panels made from organic materials. And although the best silicon solar cells have an efficiency of 40%, nevertheless they show very strong interest in polymer batteries around the world. True, the technology for the production of such batteries is still at an early stage of its development.

The first polymer batteries commercially launched in Denmark.

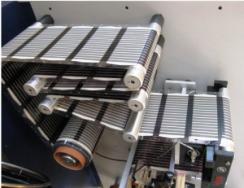

Recently Danish company Mekoprint A / S launched the first line on which polymer solar batteries will be produced. The company has been engaged in design and development work for about 10 years and is now ready for mass production of such batteries.

Production consists of multi-layer printing of a solar photocell onto a flexible film, which can then be twisted, cut and made of solar panels of absolutely any size.

According to company specialists, the main plus of polymer batteries is their low cost. Their production will cost the company at least 2 times cheaper than the production of conventional silicon batteries. This circumstance, in turn, will affect the market value of polymer batteries and as a result they will become much more affordable.

According to company specialists, the main plus of polymer batteries is their low cost. Their production will cost the company at least 2 times cheaper than the production of conventional silicon batteries. This circumstance, in turn, will affect the market value of polymer batteries and as a result they will become much more affordable.

The second plus of polymer batteries is their tremendous flexibility. Such a battery - can be cut with a knife, can be turned into a tube, can be glued to any surface of a completely arbitrary shape.

If desired, such a battery can even be glued on clothes (which was once done by Danish specialists). The polymer battery was glued to a regular hat. And in sunny weather, the battery power was enough for a small portable radio to work from it.

And finally, one cannot fail to mention the cleanliness of the production process of such batteries. It turns out. their production is no more harmful than the production of ordinary plastic utensils and the harmful emissions into the atmosphere that occur during the production of ordinary silicon batteries can soon be forgotten.

It is possible that after some time we will forget about gas and coal, since with the further development of this technology it is quite possible that the generated electricity using solar polymer batteries will be cheaper than the process of generating electricity by burning traditional energy sources.

See also at e.imadeself.com

: