Categories: Featured Articles » Interesting electrical news

Number of views: 28668

Comments on the article: 0

Installation of a film heat-insulated floor

Film floor heaters have obvious advantages over cable heaters:

Film floor heaters have obvious advantages over cable heaters:

1. Installation film floor heating carried out in just a few hours.

2. There is no need to open the floor.

3. There is no need to make a screed.

4. The film heater can be installed under any coating: laminate, parquet, linoleum.

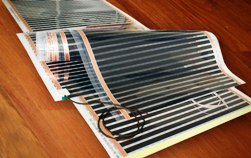

We examine the system of film insulation material for the floor. Its central thickness is approximately half a millimeter. A similar heater is made from glued dacron films. Between these films are conductors (silver or copper), and a heating graphite element.

The electric power of the film heater is 120 - 150 W per one square meter. It can act not only as an additional, but also as a main heating system.

In order to independently put a warm floor in your home, you need to buy a film heater (roll), in proportion to the area requiring insulation.

You will need: a film heater that reflects insulation material (this is a special type of insulation material with a heat layer that reflects and directs up the air warmed by the film heater so that the heater warms the room, not the floor base); electric wires, insulating tape, masking tape, copper clamps, fiberglass construction mesh, temperature controller and temperature sensors.

By a sensor, i.e., a temperature meter, it is worthwhile to understand a special device designed to measure temperature with the help of a built-in thermometer. The temperature sensor processes information using the program embedded in it, or sends a signal, which is converted into a special program code, to the main device.

The reaction of the equipment to the incoming signal is called precisely by the code, for example, turning off the heater or connecting it (temperature meters are sold in all organizations that provide film heaters).

The process of installing a film underfloor heating in steps:

- First remove the floor covering.

- First remove the floor covering.

- On a clean surface of the floor it is necessary to lay (can be glued) heat-reflecting material and spread the film on it.

- Then, a temperature sensor is installed under the film heater, namely under the heating area. In order to prevent irregularities, it is necessary to make a recess in the floor for the sensor.

- After that, with masking tape, you need to attach the film to the heat-reflecting coating.

- Install temperature controller near with a power outlet or switch.

- Fix the copper clip to the edges of the film and connect the wires to the film (the first wire connects to only 1 corner of all the bands of the heating film, the second wire covers the left and right corners on one side of the film).

- It is necessary to insulate the junction of the film and the wire, including the cut of the film.

- Make sure the system is working.

- It is necessary to lay holes in the film and the heat-reflecting layer for the passage of cement or tile glue to lay the tiles and insulate the film at the cut point.

- Place fiberglass mesh on the film.

- After that, lay the floor covering on the fiberglass mesh (tile, laminate, linoleum, etc.).

In more detail, the installation process of a film warm floor is usually described step by step and illustrated in the catalogs of manufacturers, but, in general, the installation technology for all brands of film warm floor is the same and corresponds to the order described in this article.

Mikhail Barsukov

See also at e.imadeself.com

: